clone of Weihenstephaner Dunkelweizen. If you haven't tried it, do yourself a favor and go get some! Later, I think I wished I would have cloned the old Magic Hat St. Gootz... that stuff was so good, it's a shame they stopped making it.

clone of Weihenstephaner Dunkelweizen. If you haven't tried it, do yourself a favor and go get some! Later, I think I wished I would have cloned the old Magic Hat St. Gootz... that stuff was so good, it's a shame they stopped making it.Recipe:

5# Pilsner 2row (Ger)

5# Wheat Malt (Ger)

1# Honey Malt

1/2# Special B

1/2# Rice Hulls

1oz Mt Hood (in place of Hallertau)

Wyeast 3068 - Weihenstephaner Weizen

1/17 BREW DAY: This was my 2nd all grain batch, 1st in the cooler, and we were gonna have some company over while I was brewing, not optimal, but oh well. Heated up 15 quarts of tap water to 170F, added to cooler, then doughed in. Hit my mash temp of 153, covered with 2 blankets and let sit for an hour. I did open it up a few times to check the temp since it was the first time I had used the new cooler mash tun. By 60 min, I only had lost 2 degrees, so this thing rocked! I heated up about 8.5 quarts of water to almost boiling, added it to the mash for mash out, stirred the shit out of the mash, then let sit for 10 minutes. Vorlof'd back in, then collected first runnings. Brix = 11.5/1.045... hmmmmm, that's not that great. Estimated pre-boil gravity was 1.051.. and the first runnings didn't even hit that... eesh. (I later realized that I didn't stir it enough and I think there were some pretty big clumps in there). After first collection, I had about 3.5 gallons, and I want 6.5 total so I heated up 3 more gallons to 190 and added that to the grains. Hit my 168 temp, vorlof on top, collected second runnings, total Brix now = 9.75/1.038. Shit! Ended up with 6.5, threw on the fire and brought to a boil. Added my hops when boil started... let the boil go for 1 hour. It was actually warm enough (high 30's maybe 40) that I was able to use the outdoor hose, so I used the IWC and got it down to 65 in about 15/20 mins. SG BRix=10.5/1.042... target was 1.059 for 75% efficiency, so I came in low, around 53%... oh well, what can ya do... it was only batch #2. Pitched the yeast slurry started a day before, and called it a day (aside from cleanup).

It started a pretty vigorous fermentation the next day, to the point that it looked pretty crazy. You could actually see it swirling around in the main body of the carboy. I may have seen that once before, can't really recall.

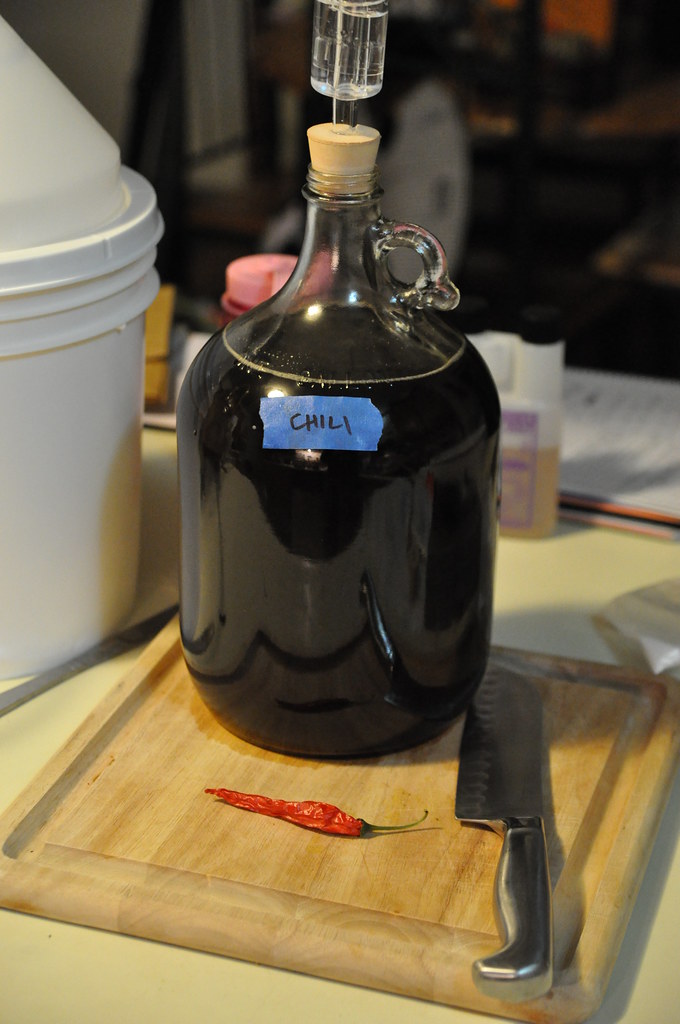

1/29 RACK TO SECONDARY: I got a bit weirded out while transferring to secondary. Some unknown substance got into the batch and there was a huge "thing" on the inside wall of the carboy (see pic). Freaked-me-the-eff-out. I took a sample, Brix=6/1.014 which hit my target, and I tasted the sample. Hmmm, not sure about this one. I took this pic in to my LHBS, and they were a little weirded out by it too, BUT she suggested that I keep moving forward with it and see how it turns out. Oooookay! I will try.

2/13 BOTTLED: Ehhh.... this still has a weird taste to it... although I can smell the banana of the yeast, which is cool.

2/23 TASTING: No carbonation at all... which makes me wonder. Plus it really did not taste good. I'm so ready to pitch this into the garden and start over. I'll wait it out a little bit longer, but there should have been some sort of carbonation in there by now.

4/4 TASTING (AGAIN): Took pic at top of post, carbonated just fine, but it did take a while. Still has this strange aftertaste. I've looked into it a bit and it sounds like its an astringent taste. Like having paper towel on the back of your tongue. I don't like it. It does look and smell great though. I have a feeling I messed up with the mashing somewhere and got some unwanted tannins... and speaking of, I had a nice chat on Beer Advocate Homebrew Forum about it - Unwanted Tannins

5/1 HOMEBREW COMPETITION: Upon the suggestion of two friends and certified beer judges, I submitted this one to the local homebrew competition. It faired better than I thought, but still not great. My astringency suspicions were supported by both judges that tried it. I'm thinking it was a combination of using crappy city tap water along with a sloppy sparge. I will definitely make this again, but I do want to tweak some stuff, and make it more like the Magic Hat St. Gootz. Below are the two score sheets.