|

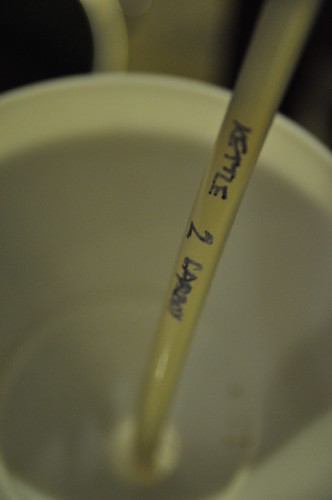

| Dry hopping 2 oz simcoe, 1/2 amarillo, & 1/2 citra |

My friend Geoff brought a couple bottles of Bell's Hopslam to our last beer tasting... holy cow... I must brew a clone. This DIPA has a powerful hop aroma, but only about 66 IBU's, so not intensely bitter. It also uses a healthy dose of honey that adds to the flavor, and is dry hopped with 2 oz of simcoe and a 1/2 oz of amarillo to give it a nice citrusy hop bouquet.

RECIPE:

SG: 1.087

FG: 1.010

ABV: 10%

13# 2-row

1/4# Aromatic

3/4# Crystal 60L (darker than I wanted, but only had access to 10, 60, 90, and 120)

3# Honey (from Honey Gardens Apiary, Ferrisburgh VT)

2 oz Simcoe 12.7% (75)

1 oz Willamette 5.2% (60) (substitute for glacier)

1.5 oz Centennial 10.5% (20)

1 oz Willamette 5.2% (15) (substitute for glacier)

1 oz Homegrown Saaz 3-5% (10) (in place of vanguard)

1 oz Crystal 5.6% (0)

1 oz Hallertau 4.2% (0)

2 oz Simcoe (dry hop 1 week)

1/2 oz Amarillo (dry hop 1 week)

Big starter of Wyeast 1056

Mash at 152 (or 148) for 60

Boil for 75

Ferment at 68F

11/19 YEAST STARTER:

Almost forgot to get a yeast starter going ahead of time. I smacked an Activator pack of Wyeast 1056 last night, was nice and ready this morning... made a 2.2L starter this morning (after consulting Mr. Malty's yeast pitch calculator), chilled to 70, pitched the yeast, and put on a stir plate. I'm not planning on pitching until noon-ish on Saturday, so that will give it 28 hrs or so to get going, which is about where I like it (31 seems to be my magic number).

11/20 BREWDAY:

Going back to single infusion batch sparge since its getting a little too cold outside to use my 3 tier kettle system (that leaks a ridiculous amount of heat). Looking to mash around 152, although some people are saying 150 or even 148. I'm thinking I could go as high as 152 and still leave space for the honey in the boil. Target mash - 14# grain, 17.5 qts of water... target is 152.

17.5 qts @ 169, added to pre-heated cooler, temp down to 164.5

4PM - doughed in, temp @ 150 (wanted 152, but this was fine) I wrapped the cooler in three blankets, and had to leave to pick Jen up from work. By the time we got home, and I got back to the cooler, it was a little over 90 minutes since I doughed in and the temp was still right on the money at 150. Awesome.

6PM (time kind of got away from me) I started collecting my first runnings, and got a quick gravity reading - Brix 21.6/1.090. Sweet. Unfortunately I only collected about 2 gallons... pretty weak. I had about 4 and a half in there to start. Darker than I expected, but not bad. Nice and sweet, with a little roast flavor (Crystal 60?).

I had been heating up 3 gallons of sparge water to 170, so I added that, collected another 3 gallons to get right around 5 gallons total, and the 2nd runnings were 8.4/1.033. I needed a little bit more so I heated another 2 gallons and added that, collected about 1.5 gallons, to top off about 6.6 gallons.

Pre-Boil is not lookin good - reluctantly, I'm calling it about a 12.4/1.050, :-\

Looking back, I should have accounted for the 1/2 gallon of yeast slurry I'd be pitching into this, so I'll be boiling this down a little longer than I originally planned... probably 90 minutes instead of 75. The last two additions I feel like came out really bitter or astringent or something. I'm wondering if washing the grains pulled out some unwanted tanins. I'll be pissed if I screwed that up.

I'll blame the wind, but this thing took forever to boil - finally started about 9:10, so I'm doing a 95 mintues boil, and adding the hop addtions starting at 75 minutes left. I'll be using almost all whole hops, primarily from Freshops.com, love that place. I'll also be using an ounce of homegrown Saaz in place of Vanguard. I'd love to be able to brew indoors and cut the propane burner out of the equation... but I'm just not set up to do so unfortunately. Someday...

Well, in a kind of on-the-fly decision, I moved indoors just now and am trying to do the rest of this brew on the stovetop. It's not a great place for it since its an electric range, but, it's doing the job so far. It's actually boiling harder in here than it was outside. Which makes me think that I'll need to be cautious of boil-overs. As long as Jen can tolerate the aroma, then this might just be the new method. We'll see.

(note: I have more to add from brew day, just haven't gotten around to it yet)

12/4 SECONDARY:

Prior to racking to 2nd, I pulled a sample to check the gravity - Brix 8.2/1.001... this seems highly unlikely. I may pull a bigger sample and do a hydrometer reading.

Some tasting remarks: Dark gold color, slightly hazy but not bad. It smelled of grapefruit, had a pretty bitter bite, but but the honey really smooths it out. A bit of an alcohol burn, but really not bad at all. I was thinking about letting this sit for another week in primary before dry hopping it... we'll see.

12/16 GRAVITY CHECK:

After a friend and fellow brewer politely slapped my hand for using my refractometer post-fermentation... I thought I better dust off my trusty hydrometer and get a better gravity reading. I begrudgingly pulled out a 3 or 4 ounce sample, gave it a spin and it leveled out about 1.008, maybe 1.007. That's a little more normal than the 1.001, and it puts the beer at just over 10%. Smells and tastes fantastic, I can't wait to bottle this up!

12/18 BOTTLING:

Two weeks with dry hops and I say it's ready to roll. I was able to bottle 17 22 ounce bombers, as well as a 12 pack of 12 ounce bottles. I can't get over how crystal clear this is... and the amazing grapefruit nose from all the hops. It hits you with a mild bitter up front, then finishes very smooth from the honey. Wow... I can't wait for this to be ready to drink! This is really the only beer I've enjoyed while bottling. I usually pour a small 2 or 3 ounce sample to check gravity and clarity... ended up enjoying that one that I poured two more samples. Lovin it.

12/27 TASTING:

While we were back in PA visiting family for the holidays, I had a couple friends over and did a small sampling of 4 or 5 of my homebrews. I decided to try this one out, it had been 9 days since bottling, so there should be some sort of carbonation present. Well, I was way wrong. This stuff was dead flat. I'm hoping that it just needs more time rather than more yeast :-S

1/5 RE-PITCHING:

After chatting with my friend Matt who had also had a flat bottle, and trying one of the 12 ounce bottles which was also dead flat... I decided to open all of these, add a pinch of champagne yeast, recap, and wait. I started with the 12 ounce bottles... when I noticed that they were actually popping a bit. I re-pitched yeast in about 6 bottles, and by the 7th, it gave a decent pop so I tried pouring it into a glass. Surprisingly, it actually had some carbonation. Not really enough... but more so than a week ago. I stopped the uncapping process and decided to put them in a warm spot and wait another 2 or so weeks. 14 days from now would make it about 1 month from when I bottled... which is about right. Shouldn't have rushed it!